- amada

- TOOLING

NEX III Tooling (Energy saving tool)

![]()

FEATURES:

- Digital Tooling Environment.

- Simple Maintenance.

- High Quality Performance.

- Running Cost Reduction.

![]()

Contouring Tool [Complex shapes without Special or Semi-Standard tooling]

![]()

FEATURES:

- Nibbling with pitch less than material thickness

- Complex internal and external shapes without special tools

- Power Vacuum Unit

- High Hit Rate

![]()

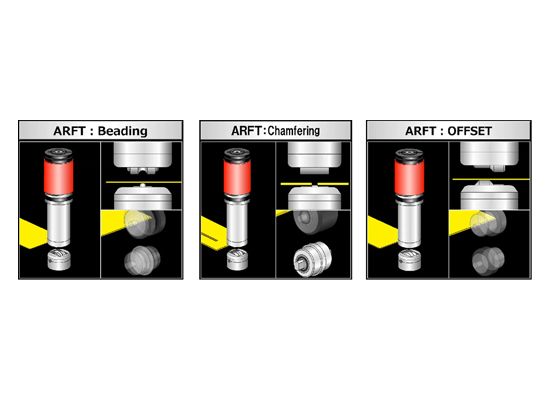

ARFT (Amada Rapid Forming Tool)

![]()

With the processing technology of the latest machine and ARFT, the time required for forming is significantly reduced.

![]()

V-Cut Tools

![]()

- Acute Outer Radius

- Hemming Tonnage Reduction

- Hole Distortion Reduction

- Short Flange Bending

![]()

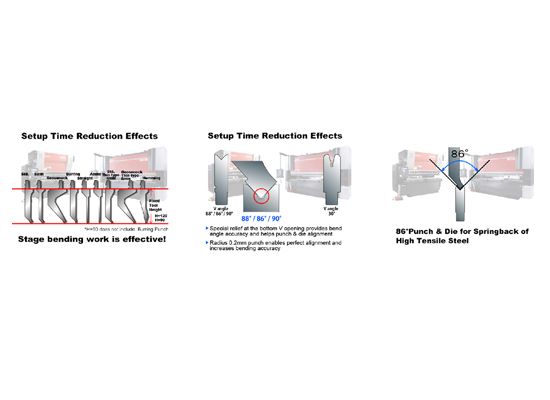

AFH Tooling

![]()

- Tooling Setup Frequency Reduction by Stage Bending

- Tooling setup time Reduction by AGRIP

- Enlargement of Return Bend Area

- Secure Punch and Die Alignment Work

- Improvement in Success Rate of Dr.ABE_BEND

![]()

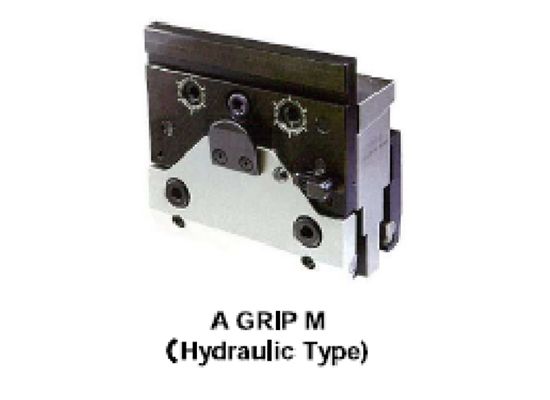

Hydraulic Clamping Holder A GRIP

![]()

- Fall prevention groves mechanisms of A GRIP main unit and tools

- A GRIP can be installed tightly and continuously

- Enables to one touch clamp of the tools by lever operation

- Dial type wedge adjustment mechanism

- Automatic tool raising mechanism (Do not need adjust the alignment of tool by press)

- Enables to front installation/front removal of the tools

![]()

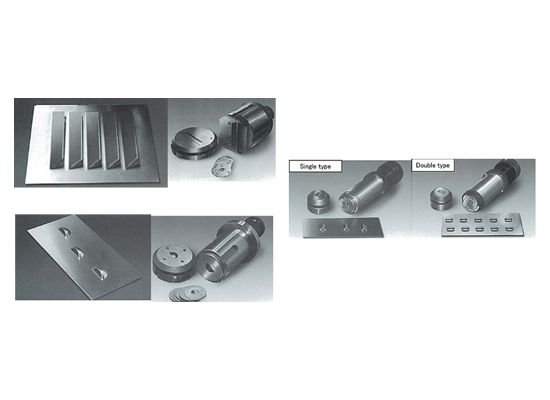

AMADA Modular Tooling System

![]()

The AMTS reduces the tool change and setup time to about one-fifth of that required in the past.

![]()

Special Order Tooling

![]()

For air flow, decoration, location marker, shear tab, wire harnesses or clip attachment

![]()

High Speed Marking Tools

![]()

Features & Specification

- Dot marking can be performed on EM/AE by utilizing high speed capacity.

- AP100 availability enables flexible marking including drawing and letters.

- Air-blow type enables intensive hit counts.

![]()

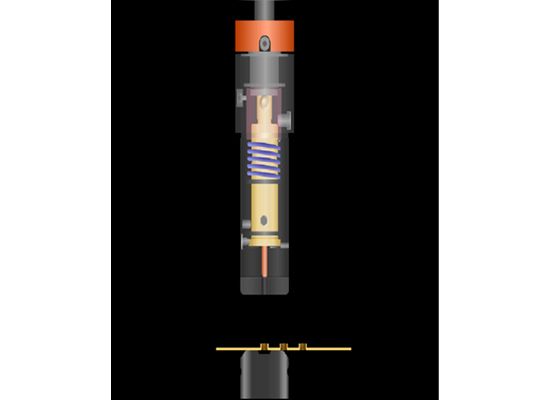

MPT Tapping Tools

![]()

FEATURES

Tapping work can be integrated by MPT Tapping Tool.

- Stripper-free structure reduces processing restriction for tap work and forming.

- Tap break detecting function reduces defects.

- Processing range is same as punching, so change of clamping/coordinates are needless.

- Both cutting tap and forming tap can be used by changing tap and conditions.

- Shear-pin reduces risk of tooling damage.

![]()

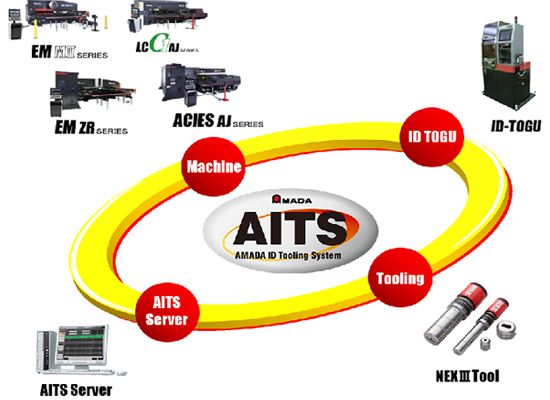

AITS (Amada ID Tooling System)

![]()

Amada has introduced a new tooling ID tooling system. ID tooling is respectively managed by ID number that links “tooling” with information. The situation of the shop floor keeps changing constantly, but the centralized management by digitalizing information can deal with it. The information of ID tooling is always shared with shop floor and office, and brings the optimal tooling management and stable processing.

![]()

Standard Tooling

![]()

NEX III tools ensure the ultimate performance of EMZR type machines using AMADA’s unique digital tool management ID marking system.

![]()