- amada

- SOFTWARE

VPSS 4ie

![]()

- VPSS 4ie is a 4D sheet metal engineering system that promotes smart factories in customer factories.

- Innovative was added to the VPSS 3i product concept of Intelligent, Interactive and Integrated.

- Furthermore, it has been renewed as VPSS 4ie under the banner of Easy, Efficiency, Environmental and Evolution.

- Intelligence and automation of sheet metal processing technology is being enhanced more than ever before, The digitalization of machining know-how in all processes and the linkage of machines, software and people in the factory have revolutionary effects.

![]()

Production Designer

![]()

The Production Designer will create unfold of each sheet metal part in the assembly and will generate individual part modules

![]()

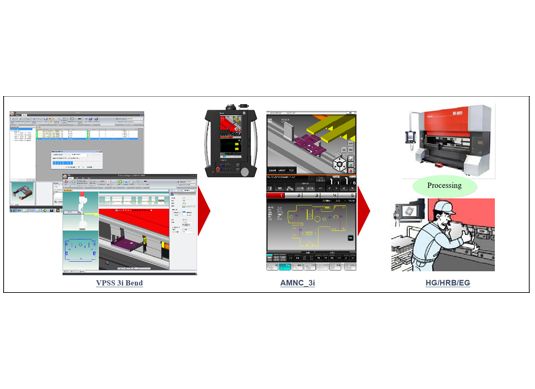

Bend Plus

![]()

VPSS 3i Bend is required to create a bending data for HG / HRB / EG / HG-ATC machine series. This software is a global software that is incorporated the demand from domestic and overseas market. and realized “easy and understandable” operation by using a high quality sheet metal model. VPSS 3i Bend plus is VPSS system for the new generation.

![]()

Blank Plus

![]()

VPSS3i BLANK is a blank CAM software to enable the continuous stable processing and supported the assembly unit for tooling assignment.

![]()

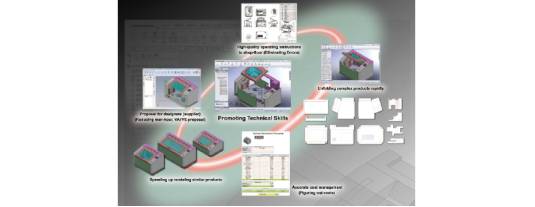

SheetWorks for Unfold

![]()

CAD serves as bridge between designing and manufacturing. Many manufacturers use CAD software for unfolding.

![]()

![]()

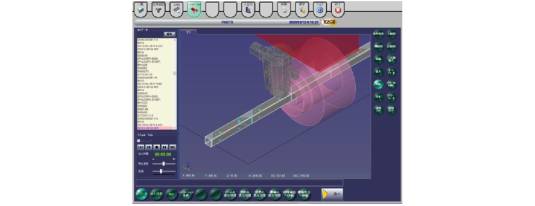

Dr. ABE Tube

![]()

CAD/CAM system featuring CAD software for 3D modelling and creation of 2D development diagrams for pipe shapes, plus CAM software for preparing data for processing using laser machines (CAD software required SheetWorks for Unfold).

![]()

AITS Software

![]()

AITS stands for Amada ID Tooling System which helps in monitoring and managing the tool usage. Each component of the tools are equipped with unique laser-etched data matrix code for easy tool management. All information of the ID tools are stored and updated in AITS software.

![]()

My V-factory

![]()

A realistic working model of the factory along with the working status of the individual machines, product information being manufactured is shown, It displays the result information in real-time using a Virtual image of the factory.

![]()