- amada

- laser-machines

- REGIUS-AJe Series

REGIUS-AJe Series

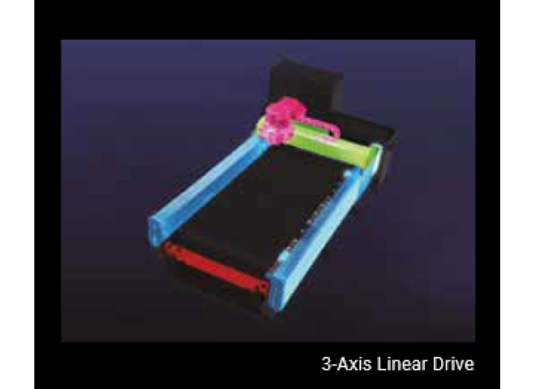

Ultra high-speed 3-axis linear drive/Fiber Laser Cutting Machine

Full linear drive with beam control and autonomous functions. Equipped with unprecedented ultra-high-speed processing with linear drive and a variety of support functions

Full 3-Axis linear drive

![]()

Linear drive technology provides very high point-to-point positioning speeds whilst also retaining the ability to provide very high accuracy, even at these increased speeds. Closed loop feedback ensures he accuracy remains consistent at all times.

The REGIUS-AJ also features intelligent head control which further improves the machine productivity by looking ahead to the next profile to be processed and calculating the most efficient motion.

![]()

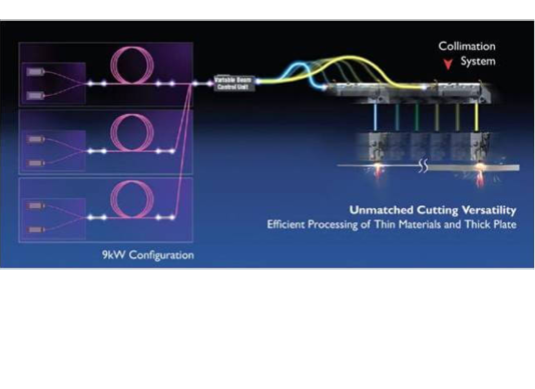

VARIABLE BEAM CONTROL TECHNOLOGY

![]()

AMADA’s original Variable Beam Control Technology automatically adapts the laser beam mode incrementally to perfectly match the material and thickness being processed. The beam mode can also be instantly changed between piercing and cutting to bring the benefit of high speed piercing and increased productivity.

![]()

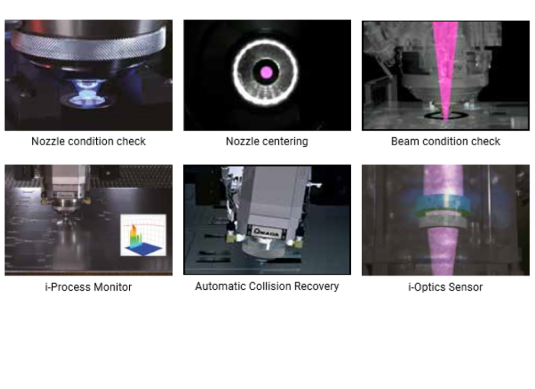

LASER INTEGRATION SYSTEM (LIS)

![]()

The new Laser Integration System incorporates several autonomous features to allow the REGIUS to perform at the highest levels of efficiency with minimal operator input, allowing less skilled employees to be utilized.

The i-Nozzle checker has e automatic functions: Nozzle condition check, nozzle centring and beam condition check.

Three other LIS functions are i-Process Monitor, Automatic Collision Recovery and i-Optics Sensor.

![]()

EASY OPERATION

![]()

ENHANCED FUNCTIONS New features of the AMNC 3i Plus control, such as camera based on-screen nesting and screen sharing provide ease of operation and efficiency

![]()

Machine Specification

| REGIUS-3015AJe | REGIUS-4020AJe | ||

|---|---|---|---|

| Axis movement X×Y×Z | mm | 3070 × 1550 × 100 | 4070 × 2050 × 100 |

| Maximum processing dimensions X×Y | mm | 3070 × 1550 | 4070 × 2050 |

| Maximum work mass | kg | 920 | 1570 |

| NC device | AMNC4ie | ||

| Control method | X, Y, Z axis (simultaneous 3 axis control) + B axis | ||

| oscillator | AMADA ENSIS-6000S / ENSIS-9000 / ENSIS-12000 | ||

| Chiller | RKE7502B-VA-UP2BP-L / RKE11002B-VA-UP2BP / RKE15002B-VA-UP2 | ||

| dust collector | JXN-6XA / JXN-7XA *1 (stand-alone/pail can type) | ||

| Axis movement method | X-axis, Y-axis, Z-axis linear motor system | ||

| Rapid traverse speed X×Y composite | m/min | 340 | |

| Processing feed speed X・Y | m/min | 0 to 240 (maximum commandable speed) | |

| Minimum setting unit | mm | 0.001 | |

Oscillator Specifications

| ENSIS-6000S | ENSIS-9000 | ENSIS-12000 | ||

|---|---|---|---|---|

| Oscillation method | Laser diode pumped fiber laser | |||

| Rated output | W | 6000 | 9000 | 12000 |

| Stability | % | ±2.0 or less | ||

| Pulse peak output | W | 6050 | 9150 | 12150 |

| Pulse frequency | Hz | 1 to 10000 | ||

| Duty | % | 0 to 100 | ||

| Wavelength | µm | 1.08 | 1080±4 | 1080±4 |

Shuttle Table Specification

| LST-3015E | ||

|---|---|---|

| Max. material dimensions X x Y | mm | 3070 x 1550 |

| Number of pallets | 2 | |